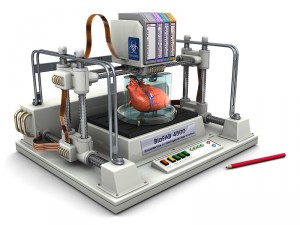

3D Printer Machine

3D printing or additive manufacturing is the process in which three-dimensional objects are created. A 3D printing machine can be compared to a robot. This machine will produce objects by successive layering. To produce an object a 3D model or computer scan is required.

Importance of 3D printing machines

3D printing came up in the early 1980’s. The first 3D printing process was based on stereolitography. The technology used by modern 3D printers is fused deposition modeling, or FDM. Most consumer-oriented 3D printing machines make use of this. 3D printing has a bright future ahead. Even president Obama recognizes the importance of 3D printers in his state of the union. You can check this awesome declaration here. The US government recognizes the potential of 3d printing and is going to invest more in this market. Keep in mind that 3D printers are not expected to replace the traditional ways of production, but will rather transform them.

Process

Typically a plastic or metal wire is  unwound from a coil into a printing nozzle. Other materials like glass, concrete and even human cells can be printed too, but are less common. In the nozzle the wire will be heated till it melts. The molten material can be used to form flattened strings, which can be used to form layers. Those strings can be extremely small, depending on the printer capacities. The nozzle can move horizontally and vertically, based on the directions given by a computer-aided software package. Right after the wire is extracted from the printing nozzle it will start to harden and thus form the desired object. FDM is a very flexible process that can produce a wide variety of products. Typical products could be shoes, toys, tools and even furniture.

unwound from a coil into a printing nozzle. Other materials like glass, concrete and even human cells can be printed too, but are less common. In the nozzle the wire will be heated till it melts. The molten material can be used to form flattened strings, which can be used to form layers. Those strings can be extremely small, depending on the printer capacities. The nozzle can move horizontally and vertically, based on the directions given by a computer-aided software package. Right after the wire is extracted from the printing nozzle it will start to harden and thus form the desired object. FDM is a very flexible process that can produce a wide variety of products. Typical products could be shoes, toys, tools and even furniture.

3D printing economic benefits

- No physical storage required, every product can be digitally stored. This can greatly decrease the investment costs for a lot of products. For example a shoe manufacturer doesn’t have to keep a whole inventory of shoes anymore that may not be sold.

- People who have their own 3D printer no longer have to go to outside to buy their product. They can just buy something online and print it in their own house. This means no shipping of any products so a lower selling price can be achieved.

- Because of 3D printing less materials will be wasted in the production phase.

- People can customize their products a lot easier and to a greater extend.

- Customized products will be created a lot faster.

Business opportunity

The manufacturing of 3D models has become big business. Only the last 10 years or so companies really started to incorporate this technology into their activities. 3D printing opportunities are endlessly. Needless to say that this kind of manufacturing will increase a lot in the next years. With more focus on the customer and the ability to answer their demands more easily, 3D printing has a bright future ahead.

With industrial 3D printers becoming less and less expensive, everybody can become a manufacturer. Easy to use software and 3D modeling tools that can answer this demand will increase in popularity and rise in value over time.

Online printing services are popping up all over the internet. They often let customers design their own products or let them choose from a wide variety of printable products. After all the market for personal 3D printers is exploding and some models are already available for a few hundred dollars. More expensive 3D printers, with their main focus on industrial printing, can range from $1000-$30000. Nevertheless, even with a small 3D printer you could start your own printing business. Putting your focus into very personal products that can be printed can make you some good money these days. Don’t forget 3D printing is already a multi-billion dollar industry with a lot of growing opportunities.

Some crazy printing facts you might not know about:

- In 2013 NASA started printing 3D rocket engine parts.

- Microsoft is creating software to support 3D printers and starts to implement this in their Windows operating system.

- The US navy used a 3D printer for submarine casings.

- A special form of 3D printing, called bio-printing, makes use of cells. Those cells will fuse together to create living tissue. Bio-printing may someday be able to print entire organs that can be used for transplant surgery.

- In China some massive 3D printing machines printed an entire house. Bringing the production cost of the house down to only $5000.

My personal predictions

My personal predictions

3D printing is going to have a huge impact on the economy. In the next decade or so, estimations are pointing towards 20% off all industrial activities that will implement 3D printing. Don’t let the ship sail without you and try to become a part of the 3D printing industry!

Share This: